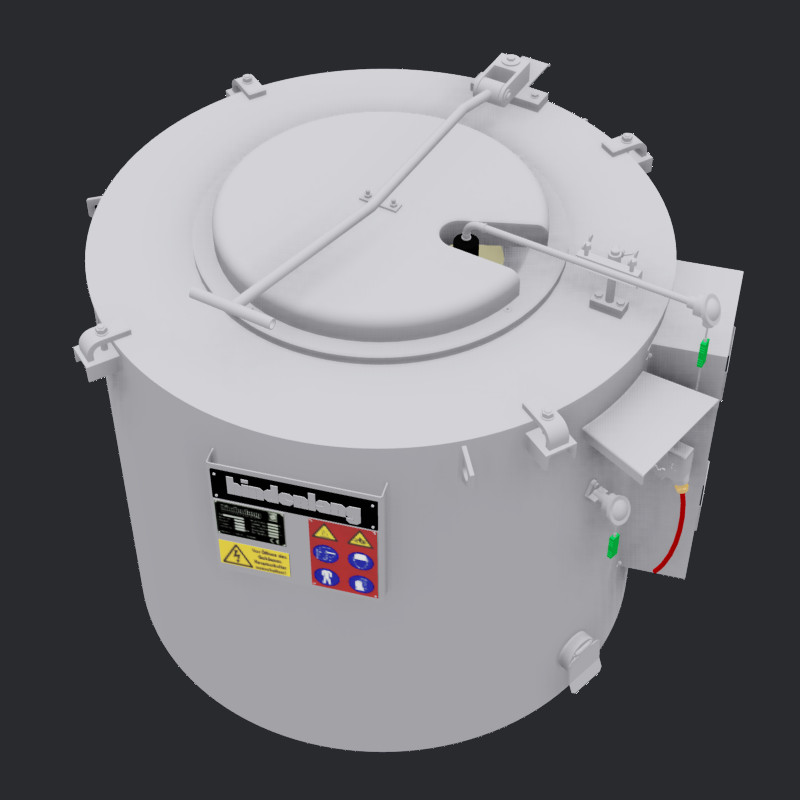

Stationary crucible furnace, electrically heated

Materials/Metals: Aluminium, Magnesium,

Heating Systems: Electrically Heated,

Processes: Melting / Holding / Dosing,

Type: SLEM / WMEP

Furnaces for bail out, melting and holding of light alloys with electric heating. Mainly used in diecasting Masch and in gravity die casts.

Also available in portable version.

Advantages of the electric furnace

- Silent operation

- Low heat losses through high-quality insulation

- No exhaust system needed

- Accurate temperature control

Crucible

- Standard design for the use of graphite or SIC crucible.

- In case of magnesium uses a steel crucible with protective gas.

Heaters

Superposed, meander-shaped heaters, each with two outwardly guided connecting bolt.

Possible cover versions:

- Without cover

- Hand – operated cover

- Hand – operated cover with swivel device

- Electromechanical cover swivel device

- Pneumatic cover swivel device

- Hydraulic cover swivel device

| Al | Pb | Zn | Mg | |

| Capacity [kg] | 250-2800 | 240-15000 | 150-2100 | 150-3000 |

| Capacity of melting [kg/h] | 110-360 | 240-3000 | 80-720 | 80-800 |

Other furnace sizes and types of metal on request.