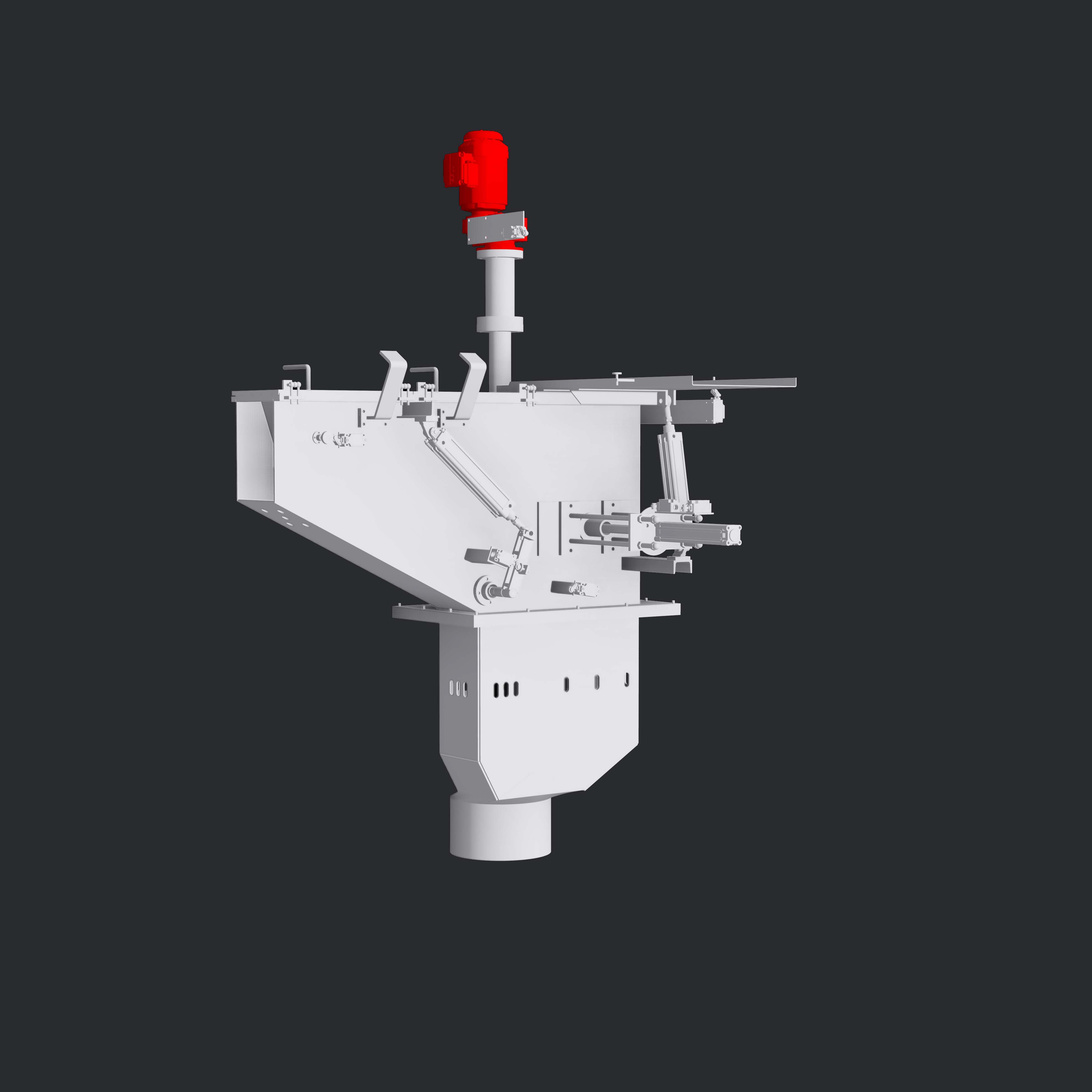

AM-Converter

Materials/Metals: Magnesium,

Processes: Melting / Holding / Dosing, Process Applications,

Type: AM Converter

The AM – Converter is a patented device that facilitates rapid melting of ingots and other magnesium solids in a furnace.

The AM – converter can also be incorporated in existing furnaces.

Advantages:

- continous material feed

- in-cell recycling

- homogenous melt

- reducing crucible sludge and dross

- lower operating costs by reducing melt losses

What is AM-converter?

The AM-converter is a patented device that facilitates rapid melting of ingots, returns and other magnesium solids in a furnace.

The AM-converter can be incorporated in an existing furnace, or integrated into the design of a new melting furnace. It is easy to install and operate.

The AM-converter technology has been successfully tested in melting equipment for diecasting. It is also suitable for a range of other magnesium melting and casting operations.

The AM-converter increases melting rates, significantly reduces melt losses and cover gas consumption, and provides improved health and safety. The formation of sludge is virtually eliminated and production of dross is also significantly reduced.

These features significantly improve the economics of magnesium melting operations.

Why change to AM-converter?

Conventional melting of magnesium for high volume diecasting applications involves the regular feeding of ingots into a melting furnace. Diecasting returns, such as biscuits or runners, are typically not fed into the melting furnace but are recycled separately. Depending on the volume of throughput and furnace design, high melt losses are often encountered in melting operations. This is due to the formation of dross and sludge.

AM-converter facilitates efficient melting of both ingots and returns with low melt losses and significantly lower operating costs.

The main operating principles of AM-converter are:

- minimisation of the melt surface area that is disturbed when magnesium ingots and solids are fed into the furnace;

- rapid melting sequence during which hot metal flows past the solids to be melted;

- maintenance of a uniform temperature throughout the volume of the melt; and

- separation of oxides which can be easily removed from the melt surface.

AM-converter provides the following:

- Direct reprocessing of runners and reject parts together with ingots

- Strong melt movement in an isolated section of the crucible without surface disturbance for the majority of the melt

- No segregation in the melting crucible giving a homogeneous alloy composition for casting or further processing

- No precipitation of intermetallics or large oxides in the melting crucible (reducing or eliminating bottom sludge)

- Rapid melting and increased furnace melting capacity

- Minimum agitation of the melt surface

- Extended crucible life

- Reduced maintenance

- Reduced cover gas consumption

- Reduced metal losses during melting, holding and casti

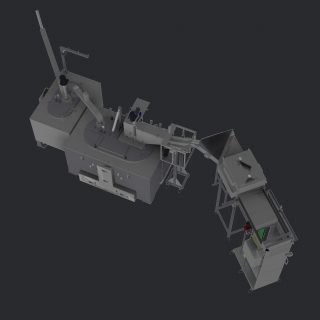

AM-Converter in combination with Mg-In-Cell-Recycling